Why Should YOU Shoot a Custom Built Arrow?

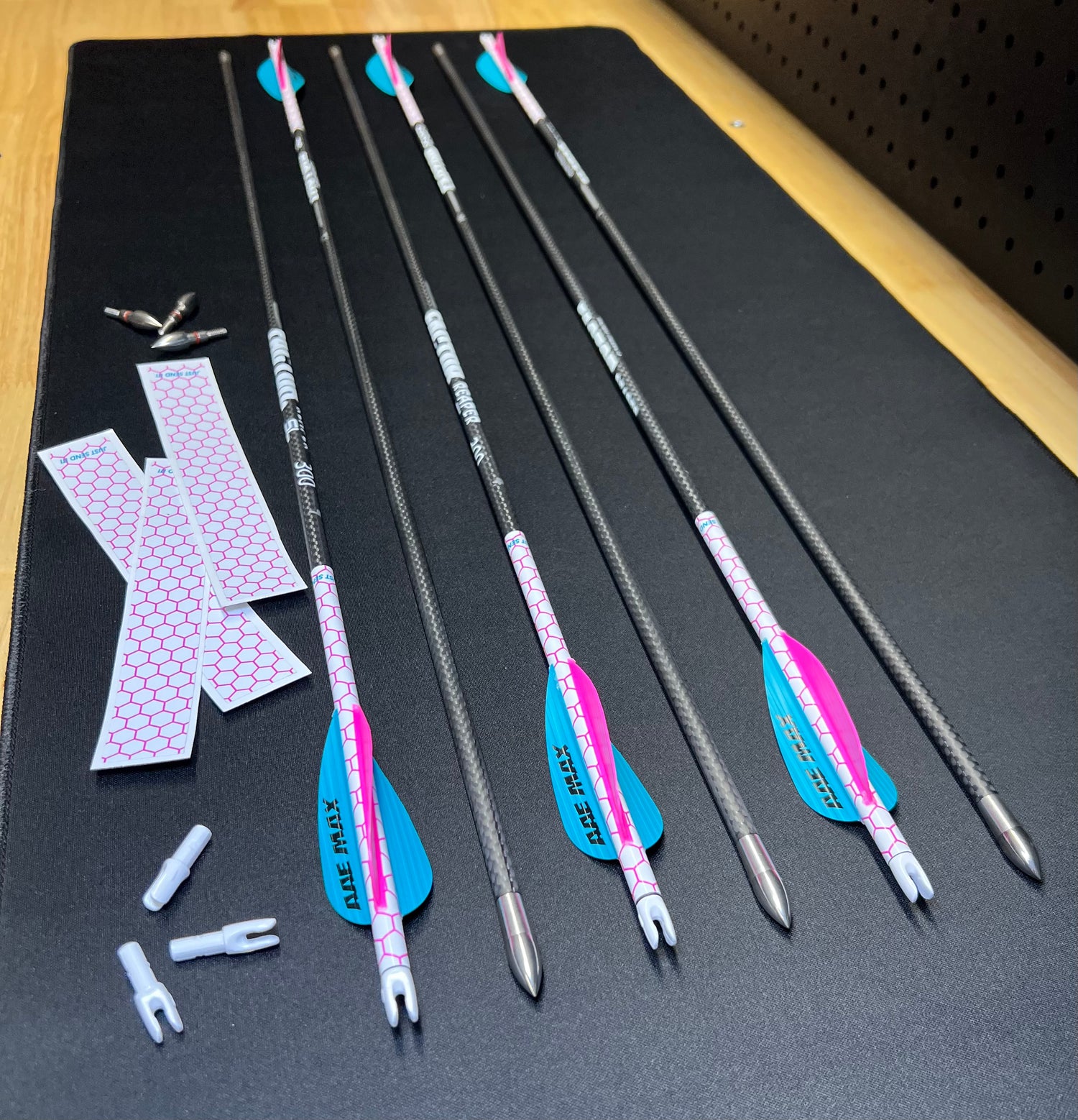

Custom arrows look awesome. There’s no denying that a flashy set of custom arrows with a custom wrap and vanes in the colour combination you selected are just freakin’ sweet. You get some satisfaction every time you nock that arrow you helped design; receive compliments from other archers; and catch them eyeing up your gear on the range. If your setup looks great - you feel great; and in turn, you shoot great. But, is there more to a custom set of arrows than just their aesthetic appeal? We’re going to take deep dive into that question; and hopefully by the end, you’ll be able to formulate an answer for yourself.

The Options.

So, what other options do you have aside from going to a custom arrow builder? The way we see it, you have 2 other options. You can either buy all the shafts, components, and tools to build your own arrows; buy a set of pre fletched arrows and have the shop cut them and install the inserts; or, you can do a combination of both. As custom arrow builders, we’d love nothing more than to take on your next arrow build; but, we know first hand the benefits that come when you decide to undertake working on your own archery equipment. Everything from just starting to fletch your own arrows all the way up to full arrow builds from scratch and tuning your own bow; all those things make you more intimate with your bow and arrow setup. We all started out here and know how working on our own equipment has improved our accuracy and our confidence in our equipment. If you have the time, patience, and attention to detail to build your own arrows we will always suggest this option to our customers; which is why at PCA we offer an extensive list of arrow building materials and tools on our website.

Cons To Pre-Fletched Arrows.

There are many reasons why an archer may decide not to build their own arrows. Lack of time, lack of experience in the sport; but probably the most prominent reason is the convenience that pre-fletched arrows bring. You can walk into an archery shop, select a dozen arrows, and walk out with arrows that are ready to shoot within 15 minutes. We could almost consider pre fletched arrows the “fast food” of arrows. They get the job done; but there are definitely better and higher quality options available. Pre-fletched arrows are mass produced which means quality control can be lacking. Vane adhesion can be sub par and vanes can easily be stripped off when shot through a target or dragged through brush while hunting. The colour of the vanes is whatever the factory had in stock that day and the style used is a generic “one size fits all” vane that might not be the most ideal choice for your setup. On that note, we have yet to see a company in the industry offer a pre fletched arrow that incorporates an arrow wrap. So when it comes to refletching your arrows, you are forced to strip and scrape the vanes off the bare carbon which risks damage to your expensive arrow shafts. Fletchings aside, when it comes to cutting your arrow shafts down to size; since the shafts already have vanes glued onto the back of the arrow, the shop has no choice but to cut the shafts from the front. On a perfectly straight arrow shaft this does not present any issues; but, if there is any straightness deviation in the arrow shaft and it happens to be on the back of the arrow where the vanes are already installed; this relinquishes any opportunity to cut off the end that has the deviation in straightness. The back or nock end of your arrow is the most critical part of your arrow to have as straight as possible. This is the sole part of your arrow that the driving force of your bow string is applied to. If this end is not straight, then the force from your string is not applied linearly to the arrow shaft; resulting in the arrow likely not coming out of the bow as straight as it should. This can cause inconsistent arrow flight from one arrow to another. When it comes to the overall cutting and installation of your insert, archery pro shops can be very busy and fast paced environments. Especially in the weeks leading up to hunting seasons. Since assembling arrows are generally considered a much simpler job compared to repairing and tuning compound bows; the least experienced employees are usually tasked with cutting the arrows and installing the inserts. Your arrows are are usually cut, cleaned with a cotton swab, and inserts glued into the shaft. Before long you are on your way out the door with your arrows ready to get some reps in. Unfortunately due to the fast paced environment of an archery pro shop, your arrow shafts are generally not squared; shafts and components are not prepped with an abrasive for best adhesion; and almost certainly not weight sorted to end up with the most consistent weight from arrow to arrow possible. Overall pre-fletched arrows from your local shop are a good option; but for those of us that are looking to take our shooting to the next level, and expect the most from ourselves and our equipment; there are better options available.

Reasons To Shoot A Custom Built Arrow.

We’ve discussed some cons to the pre-fletched arrow; but is there really a difference between them and and a custom built arrow? Aside from the flashy arrow wraps and being able to choose the style, colour, and orientation of your vanes? Although those are a few of the reasons that custom arrows are superior; that is just the tip of the iceberg. For starters, as one might assume; a custom arrow builder builds a lot of arrows in a given, week, month year, etc. Over time, like anything, they’ve refined their skills; ran into issues and found solutions. Even though they are always learning, they have developed a process that has been proven over time to provide consistent results. For the average archer who builds their own arrows, they may never build as many sets of arrows in their lifetime as a custom builder may build in a week or a month. Just due to repetition, exposure, and years refining their craft. Arrows from a professional arrow builder are not just “assembled” but rather crafted to be precision projectiles that are as much works of art as they are high functioning pieces of archery gear. Consulting with your custom builder, you can explain what your bow specs are and what you’d like to see accomplished with your arrow build. Then, from experience, they will find an arrow shaft and component combination that will get you as close to that goal as possible. Your arrow build is then built to your exact specifications by one professional builder from start to finish; with no small detail being overlooked. Throughout the whole process the arrows are constantly being critiqued and inspected for quality. Every cut, wrap, vane, etc. is inspected after installation to be sure it meets the highest quality standards. The builders reputation is on the line and only the best end product ends up in the customers quiver. Prior to cutting, every arrow spun in an arrow spinner and visually checked for straightness deviation and then cut from the end(s) that are less straight, if any. This means you can get high level match grade .001” performance from a .003” straightness arrow shaft at a fraction of the cost. If you choose, arrows can then also be spined indexed; which further adds consistency to your batch of arrows. This is done by putting each individual arrow into a device where a weight is hung from the centre of the shaft and a dial indicator is dropped onto the shaft above that. As the shaft is rotated, the builder will view the readout on the dial indicator and will verify the “stiff” side of the arrow. This is then marked on each shaft so the vanes and nock can be aligned with it. This makes for uniform arrow flight among your dozen arrows as each arrow will bend and launch the same way off the string as the next. Now, after the shaft is cut, although typically the factory end of the arrow is square, nothing is left to chance and both the cut and factory ends of the arrow are squared. For best insert adhesion, ensuring components do not pull out in targets and aiding in strengthening the front of your arrow; both shafts and inserts are prepped using an abrasive to score them; forming micro grooves for the adhesive to grab into. But, before insert installation, all arrow shafts and components are weighed and sorted from heaviest to lightest. The heaviest arrows are then paired up with the lightest components and vice versa. This makes the heavier shafts slightly lighter and the lighter shaft slightly heavier; bringing total arrow weights closer together, further adding more consistency and tighter tolerances to the batch of arrows. Premium vinyl arrow wraps are then added to the back of the arrow to customize the look of your arrow; making re-fletching a breeze; and aiding in blood identification when hunting. This also may seem like a simple task, but if done properly; the arrow shaft is prepped and cleaned so it is free from any carbon residue; arrow wrap installed; and heated with a heat gun to 'bake' the wrap onto the shaft for the best wrap to shaft adhesion. You then have the choice of many different vane styles from different manufacturers in the configuration of your choosing to further customize the look of your arrows; but most importantly, you can pick the vane style and configuration that will give you the best performance for your specific setup and goals. No “one size fits all” arrow setups. After you’ve decided the vane, colour, and configuration; every arrow is then hand fletched one at a time and inspected thoroughly before beginning to fletch the next arrow. Any defects are caught quickly; the arrow is then re-fletched; and the issue that caused the defect is identified and mitigated. Vane adhesion is a top priority to a professional builder and everything is done to ensure the best adhesion possible. Arrows can be shot through targets multiple times and dragged through the densest brush with confidence that they will not come off until you shoot them off. Which unfortunately happens to be a byproduct of shooting custom built arrows. One of the steps alone mentioned above may not be enough for an archer to notice a difference, but when the arrows are spin tested, spine indexed, ends with straightness deviations cut, both ends squared, shafts and inserts prepped then glued, and arrows wrapped and fletched with precision. When all these steps are combined, they make for an ultra accurate batch of arrows that will certainly increase performance. Not nocking your local archery shop (pun intended), as they are the backbone to the archery industry; but they just simply do not have the time to invest in a dozen arrows like a custom arrow builder does. Professional arrow builders have devoted their time to building arrows and refining their craft. So you can rest assured that when you receive a batch of arrows from a custom builder; you have in your quiver the best end product possible that those combination of materials could deliver.

Summary.

You now have the facts, it’s time to make your decision. Does a custom set of arrows hand crafted by a professional builder seem like a worthwhile investment? Or, are they nothing more than flashy arrows that are overhyped, overpriced, and no better than the pre-fletched counter parts you can walk out of your local archery shop with in half an hour? At the end of it all, no matter what you choose, we hope that the arrows in your quiver give you the utmost confidence in your bow and arrow setup; and that you feel like you are as accurate and deadly on the tournament line and in the field hunting as you can possibly be. That is what is most important.